People learned to synthesize substances and materials that surpassed all known natural compounds in characteristics in the XX century. The cost of laboratory success turned out to be unexpectedly high. Due to the abundance of synthetic materials, we faced a garbage crisis and other severe consequences for the environment.

There is only one way out of this situation: a return to nature. But what does this mean in practice? What is happening in design, construction, and science today?

In the Knife text devoted to the history of modern materials, journalist and author of the Anthropocene digest Telegram channel Olga Deryugina suggests looking into the future and getting to know more about technologies and substances that will shape our everyday life in a few years.

***

The eco-crisis has reminded us that there is no passive and eternal matter. All organisms and things in one way or another undergo changes under the influence of the environment and climate – they become stronger, grow old, break down, deteriorate, and turn into shelters for other living creatures. And even after the expiration of the “shelf life” of buildings, objects and creatures do not disappear without a trace but go through material transformation and decay. Instead of following the principle “throw away – there is no more problem,” business and science begin to look differently at material culture and what we used to consider useless rubbish.

Theorists propose to take a closer look at the ideas of waste-free production and a cyclical economy. Practitioners experiment with substances and sensors that respond to changes in the environment. Indeed, even the slightest deviations from the norm in the state of objects and organisms may indicate impending macro events. It will be easier to predict global processes if you are attentive to such shifts at the micro-level. Therefore, scientists are now actively developing and studying living technologies. In some cases, we are talking about the imitation of the natural processes of organisms using modern technologies; in others – about the hybridization of organic and inorganic elements or the editing of natural materials.

Programmable Materials

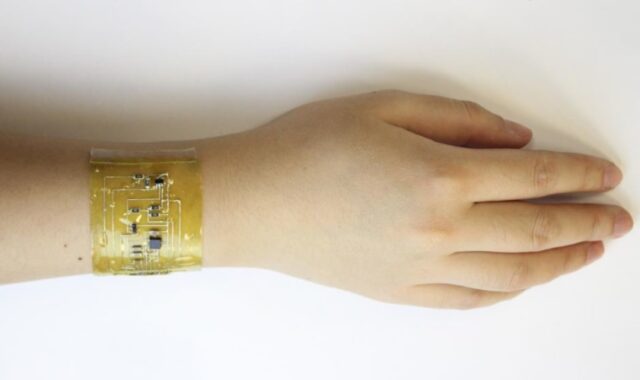

Today, engineers can create flexible, lightweight gadgets, smart textiles, and even artificial leather by miniaturizing electronic technology. Electronic skin is most in-demand in medicine – with its help, people with prostheses and transplanted tissues return sensitivity. Some developments make possible even more impressive results: for example, organic electronics, invented by engineers at Stanford University, is a thousand times more sensitive than the human epidermis. This technology is likely to find application in surgery: it will help to control instruments much more accurately and carry out operations with minimal tissue damage. A number of other benefits can be built into smart skin, such as toxic gas detection and UV protection. “Soft” electronics are eagerly tested in rehabilitation therapy, where it’s used to train damaged muscles and tissues.

Smart skin. Photo: Chuanqian Shi. A source

Experimenting with portable devices, scientists do not forget about the environment. In 2020, researchers at the University of Colorado unveiled a prototype of a new e-skin that is recyclable. Like a human, it has the ability to heal itself. The material consists of two layers of a thin film of polyimine (organic polymer), between which there is a network of wires made of liquid metal. The gadget is slightly thicker than a medical plaster. It does not lose strength and functionality even when bent and stretched in all directions. The device can measure body temperature and count the steps of its owner. Also, smart skin can recover quickly: if you connect the edges of the torn fragment, the hole will be tightened in about 13 minutes. So far, the prototype has only one drawback: it needs to be regularly recharged from the mains. However, researchers continue to work on the device and plan to relieve it of the need for external power in the future.

A common manufacturing principle distinguishes programmable materials: engineers consider the source substance’s ability to respond to changing conditions and come up with how it can be used for the benefit of the user. At the same time, electronics are not always involved.

According to MIT materials engineer Skylar Tibbits, any substance can react in some way to the applied force. The only thing left for experts to understand is how to activate this quality. Triggers can be temperature, humidity, pressure, vibration, or electricity. For example, wood expands on contact with liquid. This property has long been used in the mining industry: miners break rocks by placing a thick log in a gap between stones and then pouring water on them.

To better control the properties of a material, you need to study its structure. In the case of wood, the grain direction determines how the board will transform due to moisture. Laying out the desired contour from shavings and plastic, Tibbits and his colleagues learned to set the texture of wood artificially. When the shape is set, water is poured over the object to activate its transformation. In addition to wood, MIT engineers have tamed leather and carbon fiber.

Tibbits’ team is also developing entirely new materials. One of them is designed by analogy with human skin. It expands and contracts depending on the air temperature. In cold weather, clothes made of such fabric will fit snugly, protecting from frost and wind; on hot days, on the contrary, they will become slightly stretched, providing airflow to the body.

Using similar technology, in 2015, scientists designed a transforming boot that unfolds on its own as soon as it is taken out of a thin, almost flat package. While ordinary sneakers are made up of dozens, if not hundreds, of different materials, then the shoes of Tibbits and his colleagues are monolithic. This is its main advantage, which makes it possible to significantly simplify the process of production and subsequent processing of worn-out pairs.

Researchers are now working on custom-made orthodontic designs. In the future, having received an image of the patient’s jaw using 3D scanning, doctors will be able to create plates that do not require endless fitting and wire replacement and correct the bite without external intervention.

Living technologies

It doesn’t always make sense to resort to complex programming. Sometimes it is easier to use the valuable skills of living organisms. With this logic in mind, another team of engineers from MIT worked with colleagues from Imperial College London to figure out how to create a smart material based on bacteria and yeast. The resulting cellulose is rich in enzymes and suitable for detecting toxic compounds in the atmosphere or water purification. By varying the crops used, different functions can be assigned to the material. It will only take a few days to grow such a natural sensor. Technology has another essential advantage: to master it, you do not need a diploma from a prestigious university and deep knowledge of chemistry. It is quite possible to create a hybrid material at home. This will require a bathroom, tea with sugar, and a little patience.

Living technologies are gradually being introduced into design and construction. As with programmable materials, scientists value them for their response to external stimuli and their ability to transform.

One of the recent developments in this area is sustainable concrete based on cyanobacteria, invented by researchers at the University of Colorado Boulder in 2020. While the production of conventional concrete emits large amounts of carbon dioxide into the atmosphere, the material created by Will Srubar and his colleagues, by contrast, absorbs CO2. In this way, bacteria feed and grow, giving the building blocks a literal bloom.

Back to nature

Due to the damage that synthetic polymers cause to nature, materials scientists and designers are again interested in natural materials, particularly plastics. Various vegetables and plants are often used as raw materials. For example, the designers at Crafting Plastics Studio introduced biomaterials made from starch, sugar, and edible oil in 2018. The bioplastic, called nuatan, is the result of six years of research. It is a hybrid of two natural starch polymers. The inventors claim that this material can withstand temperatures up to 100° C and can last up to 15 years. Nuatan is biodegradable and absolutely harmless to animals and humans.

However, not all bioplastics are suitable for nature, says environmental engineer Jenna Jambek. It is essential to consider what happens to the material when its grocery life comes to an end and understand the complete production cycle. How were the raw materials grown or mined? How many resources did it take to process it? How complex is the logistics in production? All these nuances make up the “biography” of the material and determine how safe it is for the ecosystem.

Transparent wood. A source

Even if the substance has been known for a long time, modern technology allows you to edit and improve it. In particular, this approach was taken by researchers from the University of Maryland, who recently managed to obtain transparent wood. In their experiment, scientists pursued not so much aesthetic as quite practical goals: wood is much stronger and lighter than glass so that it could become more profitable building material. Similar experiments have been carried out for several years. Other studies mostly achieved the desired result by removing lignin (a natural polymer) from the wood. This is a long process, resulting in a lot of liquid waste being produced, and the wood itself becomes more fragile. In the new material, most of the lignin is retained; only the molecules responsible for color formation have been extracted. Thanks to this approach, the wood came out 50 times stronger than with a standard bleaching process. It can also transmit up to 90% of sunlight while providing better thermal insulation than glass. Researchers believe the new material could be used for windows and roofs.

The technique of editing natural ingredients also attracts physicians.

So, in Germany, they learned to make an anti-infectious nanomaterial from spider silk proteins. The resulting substance prevents bacteria and fungi’ invasion and helps to start regenerative processes in tissues.

According to experts, such a biomaterial will be relevant for producing implants, prostheses, contact lenses, and bandages.

You can experiment with natural substances at home. Researchers from the Finnish Aalto University have even collected in special book recipes that anyone can test. The authors of the publication emphasize the educational mission of the project: a modern person lacks knowledge about where materials come from and what their life cycle is. The DIY approach stimulates interest in this topic and helps to experience the importance of the cyclical economy in practice. The book results from almost a decade of collaboration between specialists in two areas – chemical engineering and design. In addition to instructions for making biomaterials, readers will find tips for setting up a home laboratory and articles on the properties of various components.

Waste as a building material

The cyclical economy, which most advocates of conscious consumption and green lifestyles rely on, assumes zero waste production or at least recycling. If you adhere to this model, designers, engineers, and architects should initially consider the possibility of multiple reincarnations of materials and objects.

Until a new reality has come, scientists are thinking about turning the garbage accumulated on the planet into a building resource. One of the methods was invented in the German studio Elegant Embellishments: designers create panels for buildings from biochar. Biochar is a by-product that comes from the combustion of wood and other organic matter. Panels made of such a material, in fact, are 90% carbon dioxide; that is, unlike other building components, they do not produce a harmful compound but absorb it into themselves.

Another safe alternative to the usual concrete and cement is liquid granite. This material is also produced from waste. It is light enough but capable of supporting the same weight as concrete. In addition, liquid granite does not melt at high temperatures (up to 1100° C).

Meanwhile, Australian scientists decided to recycle agricultural waste. According to their estimates, the agricultural industry produces millions of tons of waste biomass annually. This material is entirely recyclable. After conducting a series of studies and tests, materials scientists proposed adding biowaste from winemaking to particleboard – this is how reliable and cheap boards are obtained.

The construction industry is also experimenting with recycled plastics. According to materials scientist Sibele Cestari, technically, any plastic can be reused. Another thing is that while the technologies are not perfect and not profitable. Cestari herself has been researching synthetic polymers since 2009. Her team is testing various plastic waste mixes. Scientists add particles of newly synthesized polymers, hemp, clay, sawdust, or concrete, vary the proportions of additives and starting material in search of the ideal composition.

Picture: News 8 (from cover)

Wish Pavilion in Hong Kong. Design studio Daydreamers Design. A source

Even though the widespread introduction of building materials from recyclable materials is still far away, the first structures made of recycled plastic are already beginning to appear in different parts of the world. One of them in 2020 was presented by Daydreamers Design studio, based in Hong Kong. The pavilion, inspired by traditional Chinese architecture, was built for the annual fall festival. The tower, reaching six meters in height, is constructed of red, orange, and yellow blocks that resemble ordinary bricks. It is the largest recycled structure in Hong Kong to date.

There is another application area for plastic waste: they can be used instead of bitumen when paving roads. Such a hybrid was named plasphalt. With proper preparation of the components, the plasphalt is capable of superior strength go off the asphalt.

Science x nature

If we allow ourselves a free generalization, then we can highlight one significant difference in the approach of today’s materials scientists. In the twentieth century, researchers sought to bypass nature, to replace “imperfect” natural matter with almost flawless technologies.

Now inventors instead prefer to create “together with nature” and think about scientific and technological progress and how not to upset the delicate balance of existing ecosystems.

To achieve a more sensitive and versatile approach without neglecting the achievements of the great scientists of the past, materials science allows its interdisciplinary nature. Materials specialists should be well-versed in metallurgy, physics, and chemistry, nd have a good understanding of information technology. Most of the material scientist’s time is spent on research, but his presence is also necessary at all stages of the production of a new material, from the selection of raw materials to testing the final product.

The invention of new substances today begins not in a laboratory but on a laptop.

Special programs and digital archives help researchers identify in advance the valuable properties of components and anticipate possible difficulties in handling the material. Distributed computing and open-source software play an important role in materials science. Thanks to computer simulations, scientists save their precious time, and investors save money.

Given the hybrid nature of the discipline, the greatest discoveries in this field cannot be made without the help of colleagues. Fortunately, the Internet allows scientists to interact at a distance and quickly learn about the latest inventions and the latest tools. The Materials Project is one convenient online initiative that allows scientists to share information with colleagues and accelerate their own research. Project users get access to an international database of existing and hypothetical materials and tools for fast and accurate calculations. The number of community members is growing rapidly: 50-100 newcomers join the platform every day. The Materials Project is just one example of modern interdisciplinary collaboration. Such initiatives demonstrate that cooperation, rather than competition, is becoming the driving force of 21st-century science.Are you engaging in the waste management topic? Let’s check here how 14 years of smartphone use made a significant impact on the environment.