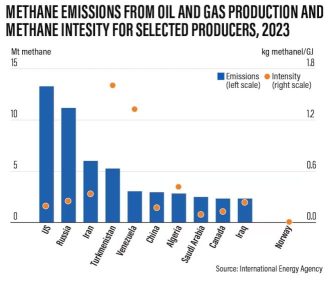

When it comes to climate change, carbon dioxide is the standout culprit and much of the world’s attempts to decarbonise and achieve Net Zero centre on the greenhouse gas.

But there are other villains in the global warming story, including fluorinated gases, nitrous oxide and methane.

Methane deserves special attention. It’s got its fingers in many pies – it’s emitted during the production and transport of coal, natural gas and oil. In farming, it’s released from livestock and other agricultural practices and it is emitted by the decay of organic waste in municipal solid waste landfills.

Even though it stays in the atmosphere for less time than carbon dioxide before breaking down, while it’s there methane is 80 per cent more efficient at global warming than carbon dioxide.

In addition, it is the primary contributor to the formation of ground-level ozone, a hazardous air pollutant that the UN calculates causes a million premature deaths a year.

Carbon dioxide remains in the atmosphere for hundreds, sometimes thousands of years, meaning even if the world suddenly emitted no carbon dioxide at all, it would still be a problem. Methane takes around ten years to break down, so tackling its levels now would seriously help the world not exceed the 1.5ºC warming target set out in the Paris Agreement.

Methane split

One UK company has come up with a patented process that turns harmful methane into climate-friendly hydrogen gas and graphene, the much heralded product of the future.

Based in the UK university city of Cambridge, Levidian does this by separating the methane molecule (CH4) into one carbon atom from the four hydrogen atoms inside it’s unique Loop system.

Levidian is specifically looking at heavy industries and agriculture – among its more than 50 clients and partners are the Emirati oil and gas company ADNOC, the UAE-based waste management firm Tadweer, the UK water company United Utilities and the Luxembourg-based construction company Stugalux.

Its first customer in the agricultural sector was Worthy farm in the English county of Somerset, the home of the world-famous Glastonbury Festival.

“As a society we’re making great progress in decarbonizing our electricity grid, like in transportation with electric vehicles,” Levidian’s chief executive, John Hartley told The National.

“But the hard-to-abate bit, the tricky bit, has been the really heavy industrial customers who use loads of heat, loads of power on their sites and have lots of waste products, and that’s really where we’re focused.”

The advantage of Levidian’s Loop system is its portability. Housed in units that are essentially shipping containers, they can be transported to wherever methane is being gathered, be that a gas field, a landfill site or a farm.

Once at a site, pre-combusted methane is fed into the Loop, at which point the patented scientific process swings into action.

“We bring in methane, ideally from a waste source, Mr Hartley told The National.

“We apply microwave energy to that methane, and at the point where we apply the microwaves, we run it through our nozzle system, which is our kind of special proprietary intellectual property, and the combination of the microwaves and the nozzle geometry causes little vortices in the gas flow.”

“The carbon becomes powered graphene material, and the rest becomes hydrogen, which you can then burn as a clean fuel.”

‘A unique and special material’

Graphene was first isolated in Manchester in the UK some 20 years ago and shouldn’t be confused with other forms of carbon like diamonds and graphite.

It’s what’s now referred to as a 2-D material – a single layer of carbon atoms that has unique and different properties.

“For example, a single atomic layer of carbon is 200 times stronger than steel,” James Baker, chief executive of Graphene@Manchester told The National.

“It’s more conductive than copper. It can act as a perfect membrane to allow some molecules to pass through and to block others. It’s quite a unique and special material, but the challenge is making it into things that are practical.”

Based at the Graphene Engineering Innovation Centre (GEIC) in Manchester, Mr Baker and his colleagues are spearheading the spread of graphene into the wider world through a myriad of applications – from making cement stronger to enabling tyres to last longer, from lighter plastics to new forms of batteries to ink and clothing.

“What we’re seeing with graphene is that already people are building houses, you can buy running shoes, tyres and an anti-corrosion coating,” he told The National.

“So, products are already on the market today. It’s starting to get into more general use in a number of cases.”

Just as Levidian has close relationships with ADNOC, Tameer and Khalifa University, the GEIC is part-funded by the UAE’s Masdar, the world-leading renewable energy company.

Down on the farm

A big potential user of Levidian’s Loop technology is the agriculture sector and the company’s first client in this area was Worthy Farm, probably better known as the site of the Glastonbury Festival.

For most of the time, Worthy Farm is a working farm in the rolling hills of the west of England. As such, its cattle herd produces slurry, which itself is a source of methane.

Helping Levidian get the Loop established at Worthy Farm, Hexla is a company that assists start-ups deploy their next generation renewable technologies into the market.

Worthy Farm was already making biogas from its cow slurry, but Hexla was able to insert a Levidian Loop into the process which meant the biogas became 17 per cent hydrogen, because the Loop was taking the hydrogen from the methane and putting it back into the biogas stream. As such, the biogas was becoming decarbonised. In addition, graphene was also produced.

“Anyone who wants to decarbonise a methane or natural gas stream, whether its agricultural, waste-water treatment or industrial, this technology is going to be quite useful,” Andy Yeow, a former natural gas trader and co-founder of Hexla told The National.

Hexla is looking to take the Levidian Loops around the world, with deployments in the US, the Middle East and Australia.

For Mr Yeow and his Hexla co-founder Peter Behrens the key to the Loop’s success is the potential commercial viability of graphene.

Theoretically, because the market value of graphene is so much higher than hydrogen, the hydrogen can be produced in the Loop for almost no cost all.

“If everyone turned round and said ’we’re going to put graphene into concrete today’, we can start building some fairly large-scale facilities that can start producing some meaningful amounts of hydrogen for the world,” Mr Yeow told The National.

“But it’s making sure that the graphene is being utilised.”

Mr Hartley said the Loop processes solves the problem of producing graphene at scale without having to resort to energy and cost-intensive graphite rock mining. It was one of the main reasons Levidian attracted investment from the UAE’s sovereign wealth fund, Mubadala.

It’s also no coincidence the first Loop to be exported from the UK went to Khalifa University in Abu Dhabi and why the Gulf region is such an important area for Levidian’s expansion in the coming years.

“That’s kind of pulled us into that region,” he told The National.

“We’ve now got three members of staff there. We’ve hired a managing director to grow the region, and the UAE will be our regional office for the Middle East more broadly.”